|

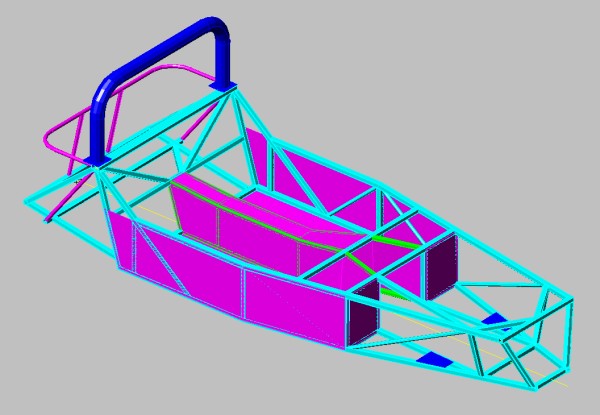

The Type 1 chassis is the chassis design documented

in the book,

Build Your Own Sports Car for Under 250 Pounds -

and Race It

written by Ron Champion (Haynes Books)

This design is usually referred to as a

LOCOST 7

and is the general starting point for all the

other

chassis designs presented here. The image below shows the

chassis structure.

|

This

chassis is constructed from round and square

rectangular tubing. The main chassis structure is

fabricated from

one inch (25 mm), 16 gauge square tube. The

transmission tunnel region is fabricated from

three-quarter inch

(19 mm) square tube. Some diagonal elements and the

rear cargo area are fabricated from 19 mm round tube.

Sheet steel of varying thicknesses is applied to

several areas.

|

|

|

The image

above shows a 3D wireframe structure used to perform a simple

stress analysis for this chassis design.

The analysis involved applying a couple (two forces of equal

size but opposite direction, to create a purely torsional

load) to the front of the frame while holding the rear of the

frame fixed. The relative rotation of the front of the

chassis under this load is an indication of the torsional

stiffness of the chassis.

|

|

The image

above shows the predicted stress levels (axial stress along

each tube) in the chassis structure

due to the

applied torsional load. The red colour indicates the most

highly stressed chassis members.

Yellow

indicates moderate stress levels while blue indicates low

stress.

This chassis was tested for theoretical torsional stiffness in

two different configurations. It was tested in the form

described in the book, with a combination of two sizes of

square tube and round tube. This gave a value

of 1219 lbs.ft/degree. The same structure was then tested

with all members using 25 mm square tube.

In

this configuration the theoretical torsional stiffness was

1219 lbs.ft / degree.

For comparison a live

test

value for a Locost 7 chassis was measured as 1187 lbs.ft / degree.

|

|