|

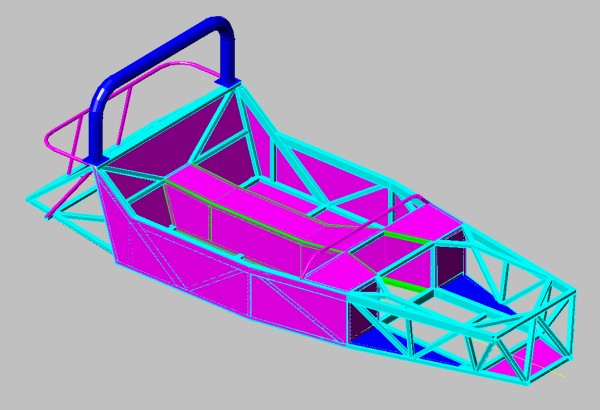

The Type 3 chassis is a modified version of the

Type 2 chassis. This design replaces some of the

25SHS tube in the more highly loaded areas with 50x25RHS

tubing. It is intended for use with a 6 cylinder

engine or small V8.

|

The

chassis is constructed from square and rectangular tubing.

All chassis members are

constructed using either 25 mm square steel tube or 50

x 25 rectangular tube, all with a

1.6 mm wall thickness.

|

|

|

The image

above shows a 3D wireframe structure used to perform a simple

stress analysis for this chassis design.

The analysis involved applying a couple (two forces of equal

size but opposite direction, to create a purely torsional

load) to the front of the frame while holding the rear of the

frame fixed. The relative rotation of the front of the

chassis under this load is an indication of the torsional

stiffness of the chassis.

|

|

The image

above shows the predicted stress levels (axial stress along

each tube) in the chassis structure

due to an

applied torsional load. The red colour indicates the most

highly stressed chassis members.

Yellow

indicates moderate stress levels while blue indicates low

stress.

This chassis was tested for theoretical torsional stiffness. A value

of 2175 lbs.ft/degree was calculated. A calculation

was also carried out to see what the stiffness value would be

if the rectangular members were replaced with

square members (to see the specific effect of using the RHS

tubing). This gave a value of 1787 lbs.ft/degree.

|

|